23 Nov 2011

The Path to a Great Tool

This post will recount my journey leading to the discovery of a fine tool manufacturer, Barr Specialty Tools. I hope you enjoy reading about the meander that launched a search for blades that are a cut above what is typically found in the market place. Near the end of the lens I’ll spotlight a couple of items that I have purchased from Barr and thoroughly enjoy using in my shop.

An Idea Germinates

I have been intrigued by timber frame structures for some time. It probably started with my assignment to Germany while serving in the U.S. Air Force. The buildings are picturesque to be sure, but it was more that that. As we traveled about I began to notice the dates carved into the old buildings. Many (if not most) of these structures predated the founding our our county. Here were homes that had been built and continuously occupied for hundreds of years. A very different approach from our throw away consumer model.

A Thought Sprouts

At some point I began to think that perhaps I should build something with timbers. The idea was nebulous for the longest time, in large measure because we were renters. Then, we bought our first house and things started to gel a bit. We did all the normal stuff after moving in to ‘our first home’. We painted, changed the carpet, and touched up here and there. Then we turned our attention to the back yard. We wanted the kids to have a play set. We looked around and discovered that most of the stuff out there was either junk or very expensive. The play structure, such as it is, lends its self to big beams. In the end I decided to build as shown in the photo here rather than buy. This first project taught me that my tool box was completely inadequate for the task.

Next stop: small garden shed. I liked the way the play set turned out and learned a lot about building with larger pieces of wood. One of the things I learned was that pressure treated pine is on the wrong side of structurally sound for this kind of work. There is no way to make anything that needs strong joints with it. When we started thinking about a shed I knew that I wanted to try a real timber frame. I got a few more tools including some chisels, a draw knife, and auger bits. When I found some cast off oak beams I was in business. This time I moved a step closer to ‘authentic’ by cutting mortise and tenon joints and using wooden pegs to hold them together. More lessons learned. Regular chisels aren’t adequate for big timber work.

The Concept Grows

The small garden shed clearly illustrated that my previous tool choices were inadequate. It also demonstrated that there are others who value timber frames. When we sold the house our buyer was adamant that the ‘barn’ had to convey. We sold in a very tough market and I think that the little shed was key to our properties sale, despite it’s rudimentary design and simple execution.

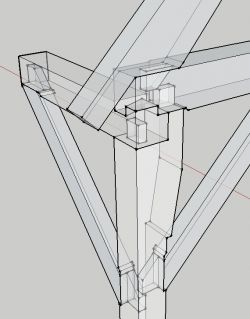

We are now in a new house with a garden shed that is too small for anything useful and about to fall down. Looks like another building project using timbers to me! This time around I have spent time learning about the craft and planing out the work. This will be a much larger project, although still in a very small footprint, because I will attempt to create more complex joints, as illustrated in the picture.

In order to cut those joints effectively, more capable chisels were required. While trying to find quality chisels and slicks the consensus seemed to be that tools of old were the best choice for satisfying the cost + quality = value equation. If you could not find an old tool most sources advised Barr Quarton was one of a few solutions that could be counted on to keep quality at an appropriate level to meet the rigors of heavy framing. Having purchased some chisels from Barr I concur. It is my hope that you will soon gain the satisfaction of making great piles of shavings using one of his tools.

Now lets see if I can finish moving the concept past the bits and bytes stage into a structure of lasting beauty….

A Notion is Realized

A Hand Forged Slick from Barr Specialty Tools. A slick is a large, hand held chisel used for cutting wood joints. While the size may lead you to believe its function is rough, high volume cutting, it is not. Instead it is a finish tool whose size and heft provide greater control for better accuracy.

I have always had an affinity for edged wood working tools. For me there is a certain satisfaction gained from making a smooth, clean cut in a piece of wood with a sharp chisel, plane, or knife. This particular slick provides that feeling in spades.

I am also becoming more enamored with the idea of purchasing directly from a craftsman or artisan. This tool also moves in this direction. While I have not had the opportunity to meet Barr from all accounts he fits into the category of smaller production, higher quality, artisan. He claims that the tools he ships are ‘sharp enough to shave’ out of the box. The first thing I did when I opened the package was test his claim – sure enough.

Footnote: here are a couple of books I have read and found to be helpful. The links will open a new window and are from the affiliate program at Amazon so if you purchase by following them I will receive a small referral that will be used to for site content development and maintenance.

. .Originally Published on Squidoo 2011 now here…